Frosted Finishes: Optically smooth and defined Roughness in one single Additive Manufacturing Process

WEMELDINGE, NETHERLANDS – NOVEMBER, 2021 – Luximprint, a global leader in offering rapid prototyping services for custom optics and Optographix, based in The Netherlands is delighted to announce the availability of its refined ‘Frosted Finish’ capabilities for application with large-format 3D printed optical features and textures. Whereas the availability of the finishes on its own is not entirely new, recent technology optimizations have taken the applicability and versatility of frosting and texturing large-format surfaces to a next level.

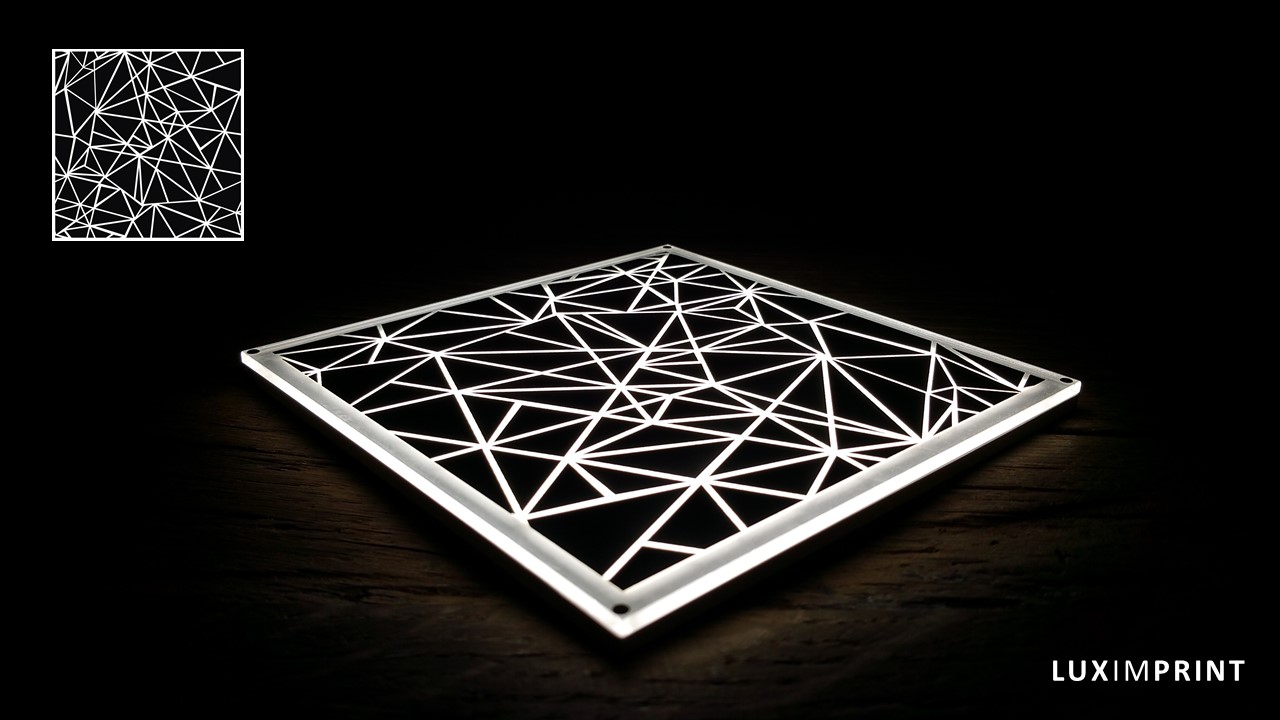

‘Frosted Finishes’ are a unique process feature directly available from the Luximprint optical 3D printing process. A distinct capability whereby random or specified geometric textures in a gradient roughness are applied by using advanced 3D printing methodologies. If required, the frosting can be applied along with optically smooth surface finishes, all in one single manufacturing process. The enhanced process feature greatly enriches a variety of printed products and applications and is now available to the global design and engineering community.

Micro-Expertise Meets Thinfilm Capabilities

By combining printed micro-structure expertise with sheet- and thinfilm capabilities, Luximprint has specified a range of defined Frosted Finishes to be applied directly onto optical and non-optical surfaces of various products generated by the process: Printed Optics, Optographix, Textured Surfaces, reflective surfaces, and finally: Printed Diffusers.

When preparing a users’ CAD file for 3D printing, either ‘smooth’ or ‘frosted’ surface definitions are typically applied: Whereas surface smoothness ensures optical clarity and performance, frosted finishes result in accurately defined or intended undefined scattering of light aiming for better light control, reflectivity, source hiding, efficiency and finally also aesthetics.

Marco de Visser, Co-Founder and Director or Marketing and Sales at Luximprint, shares his excitement about the availability of the extended process feature:

“We are delighted to have our extended range of frosted process settings implemented. For several years now, we have been utilizing frosted surface finish capabilities in a narrow sense but today, carrying an even broader portfolio to choose from, new possibilities in functional and esthetical application have arrived. Frosted Finishes greatly compliment the possibilities for our users and opens up doors to new markets and applications, while we continue to add value to those markets served today”.

Correlation Values and Mold Roughness

The correlation between the units of measure used to define frosted surface finishes and how they compare to for example mold roughness is currently under definition. In the US definitions as set forth by the Society of the Plastics Industry (SPI) are targeted, whereas European standards for measurement or for defining mold textures include Roughness Average (RA) and Root Mean Square (RMS). Fortunately, the science behind frosted finishes will be left to a qualified optics design engineer who can help achieve the surface finish that best matches his customer requirements or mirrors the final mold tool texture. Luximprint frosted finish capabilities can greatly facilitate simulating, testing and guiding that process.

Defined surface roughness can be accurately applied to optical and non-optical surfaces for a variety of purposes.

Multi-purpose Utilization

Frosted Finishes capabilities can be used for a broad variety of purposes. Most commonly, ‘wanted’ roughness is used for anti-glare reduction, most notably to avoid blinding in illumination applications. Alternative use may include the utilization of the capability to generate ‘scattering-by-purpose’, softening light beams, or just to ensure privacy (anti ‘look-through’) in crowded or discrete architectural spaces, such as meeting rooms and offices.

Peter Silva, Principal of SilvaCo Optics and Luximprint Representation for the Bay Area is delighted about the arrival of the extended capability: “The Luximprint service offering and capabilities are very attractive for those in need of fast custom optics prototypes. The ability to have frosted finishes applied along with functional optical surfaces in ONE single process, cuts the needs for additional post-processing, such as etching or sand-blasting. It cuts financial overhead and reduces handling, while providing a quick and reliable forecast about what to expect through rapidly available demonstrator parts”.

Supporting Third-Party Optics Development

Interestingly, there are other interesting opportunities arising for the use of frosting. Another service offered through the Luximprint platforms is the adoption and reworking of external (third party) developments. The process flexibility can facilitate the reworking of (optical) parts designed and fabricated by third parties that do not or not fully perform as intended, or just help to take away complexity. Healing imperfections such as aberrations or mold defects and forecasting intended tool changes (before physically implementing them) are among the most common purposes.

The service of ‘reworking’ external third-party items is a fairly unique and uncommon approach in todays’ manufacturing landscape. It may, however, avoid companies to run into unnecessary and uncertain cost-compromises. The service is primarily intended for the reworking of optical performance parts, however, different substrates and non-optical objects that need further roughness corrections can be considered. Aluminum reflective surfaces, mirror substrates, non-translucent glass substrates and plastics, just to name a few, are commonly reworked for a great variety of users and applications.

Frosted Finishes Application Areas

Frosted finishes are a process capability that’s typically used in a broad range of functional and decorative applications. The optical sheets find their way in 3D television, holography, display items, advertising displays, signage, general lighting applications, build architecture, HUD devices, among multiple others.

Contact us

Are you in search for fast, flexible and cost-effective custom optics solutions? Please don’t hesitate to contact us to discuss your next projects. With typical lead times of 5-10 business days and global delivery with local support, rapid availability of custom optics is guaranteed.