Iterative Design Processing with Printed Optics

Iterative Design Processing is a design methodology based on a cyclic process of rapid prototyping, testing, analyzing, and refining an optical product. Based on the outcome of the tests, design changes and further enhancements can be made. This way of processing optical parts is intended to ultimately improve the quality and functionality of a given optics design. Luximprint technology offers new solutions to optics design professionals to trial-and-error and validate their illumination concepts at speed.

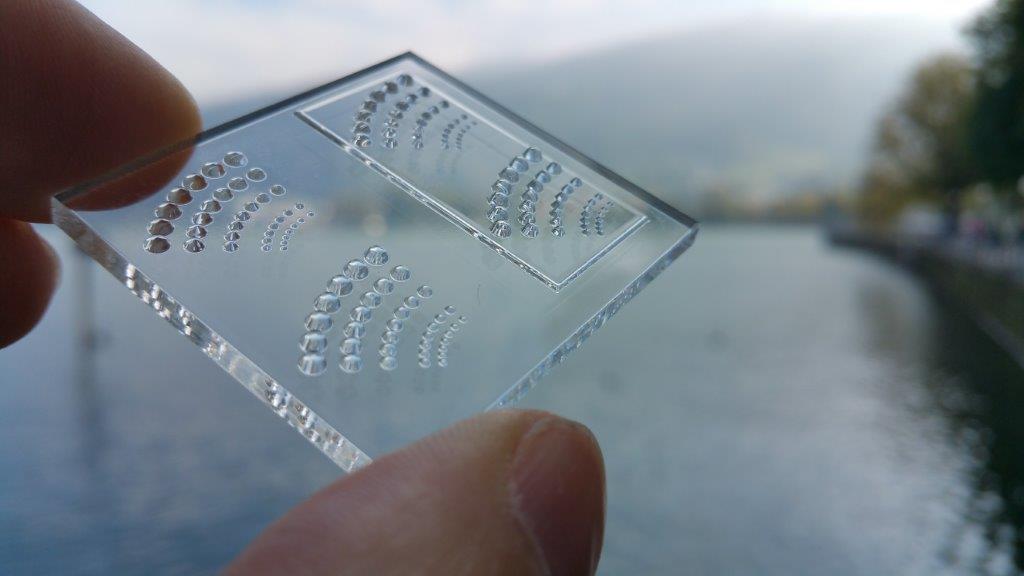

[caption id="attachment_2768" align="alignnone" width="1024"] Microlens features can easily be printed in various set-ups to find out the best suitable solution.[/caption]

Microlens features can easily be printed in various set-ups to find out the best suitable solution.[/caption]

Shorter Cycle Times and Functional Testing

The iterative optics design process may be applied throughout the full circle of the new optics development process. However, changes in design are most easy and less impactful (timewise/cost wise) to implement in the early stages of development.

Usually, the first step in the iterative design process is to develop an inspirational and/or functional optics prototype. The printed optics prototype is ideally be evaluated by a user group or at least a team that’s not associated with the product itself in order to deliver non-biased opinions in order to optimize the output.

[caption id="attachment_2769" align="alignnone" width="1024"] Iterative Design Processing of custom optics becomes extremely easy and time saving by using printed optics technology.[/caption]

Iterative Design Processing of custom optics becomes extremely easy and time saving by using printed optics technology.[/caption]

Easy Product Variations and Product Iterations by Luximprint

When creating masterpieces for new custom optics, it is interesting to know that the Luximprint process has the capability of printing multiple design variations at the same time (“Product Variations”). Should you consider the use of various product solutions for your next system development that are almost the same as the initial ‘masterpiece’ but slightly differ in function, appearance or shape (not lens type!), this might be a very interesting option. As no physical tooling is involved (and thus not the investments, time losses and MOQ’s related to it), users can easily pick-and-choose the best suiting optics solution and move forward with it to final fabrication tooling.

Should the outcome of the initial test rounds not be as positive as expected (for whatever reason), Luximprint offers the possibility to order ‘Product Iterations”. On the contrary to Product Variations, Product Iterations include a further optimized masterpiece that has evolved after the initial application and user testing. Special conditions apply.

[caption id="attachment_2770" align="alignnone" width="590"] With additive optics fabrication parts on the build platform can either be all the same or all different.[/caption]

With additive optics fabrication parts on the build platform can either be all the same or all different.[/caption]

Iterative Design Processing of Custom Optics

At Luximprint, we offer great tools and technology to optimize custom optics in an iterative way. The fast, flexible and cost-effective additive optics fabrication process enables optical engineers and system designers to trial-and-error with various set-up until the most appropriate lens solution is found.

Interested to work with us? Please don’t be afraid to talk back and get in touch with one of our design engineers!