Droplets-on-Demand

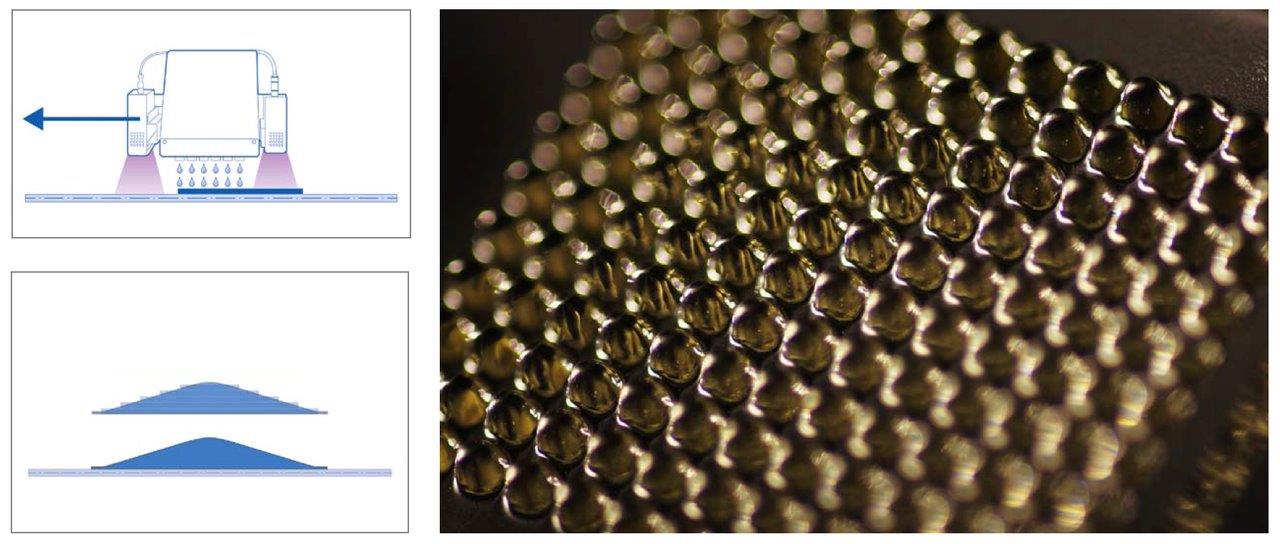

The Luximprint process 3D prints optical structures using industrial inkjet equipment, engineered for volume printing. Droplets of a transparent UV-curable acryllic “resin” are jetted onto a translucent substrate and then cured by UV-lamps which are attached to the print head. Droplets on demand, here is how it works…

The droplets are deposited in several passes until the desired form is built. The results are geometric or free-form shapes which may incorporate prisms or lenses (Optical Plastics), as well as full color graphics (Optographix) and textured surfaces.

Even though the resin is deposited in discrete drops, the final surfaces are optically smooth and fully functional. By precise control of flow and using the natural mechanism of surface tension, optical quality surfaces are achieved with no further processing.