Project Description

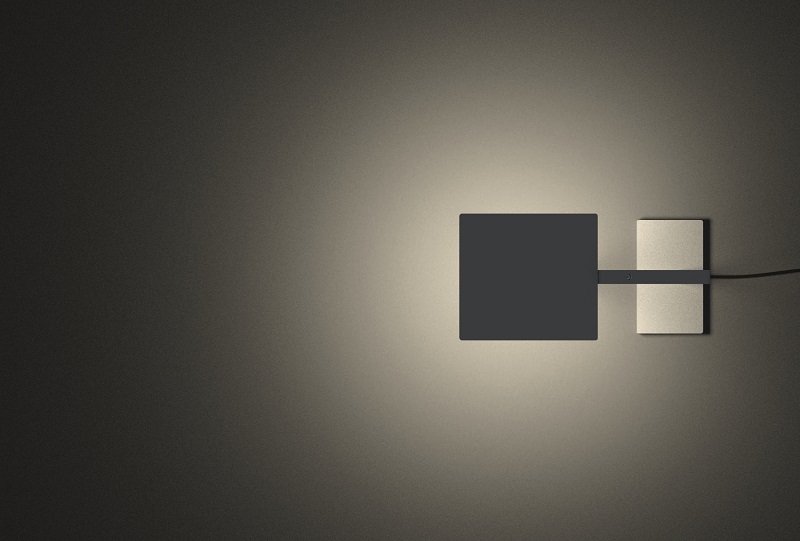

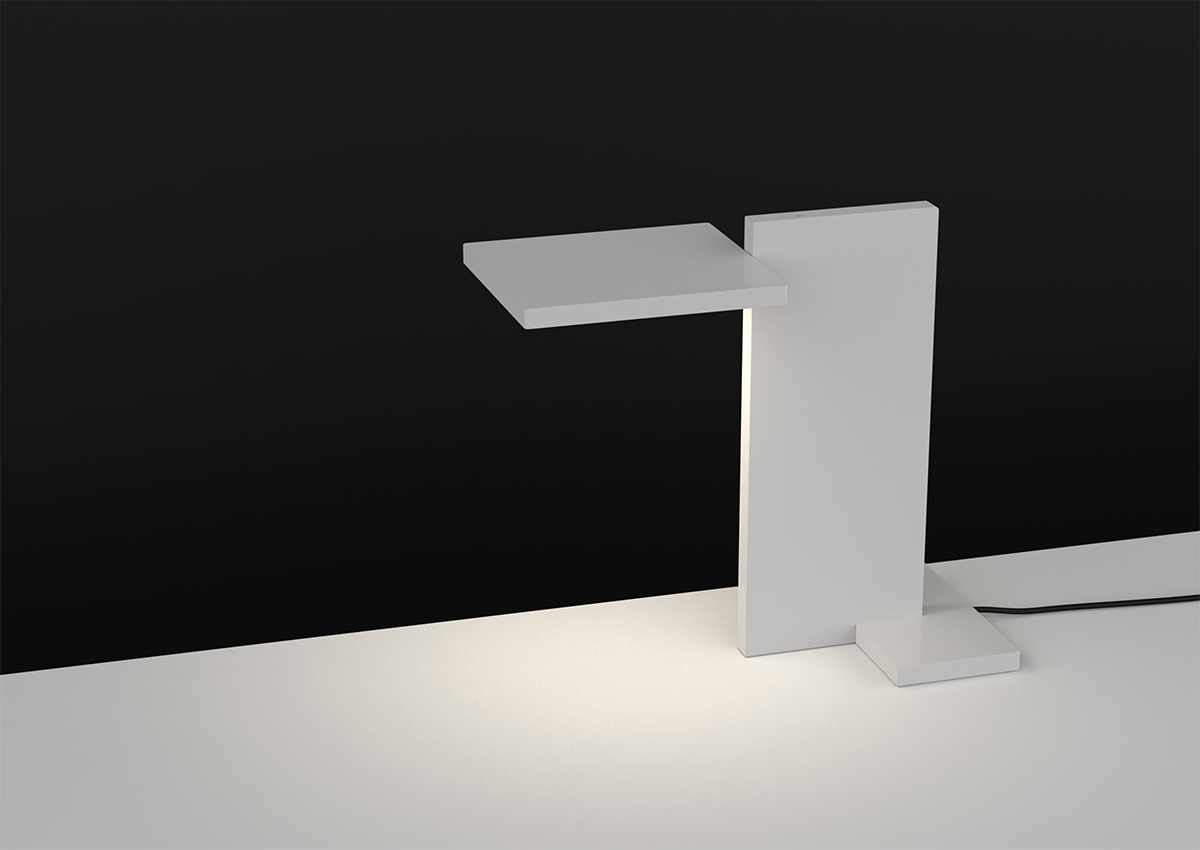

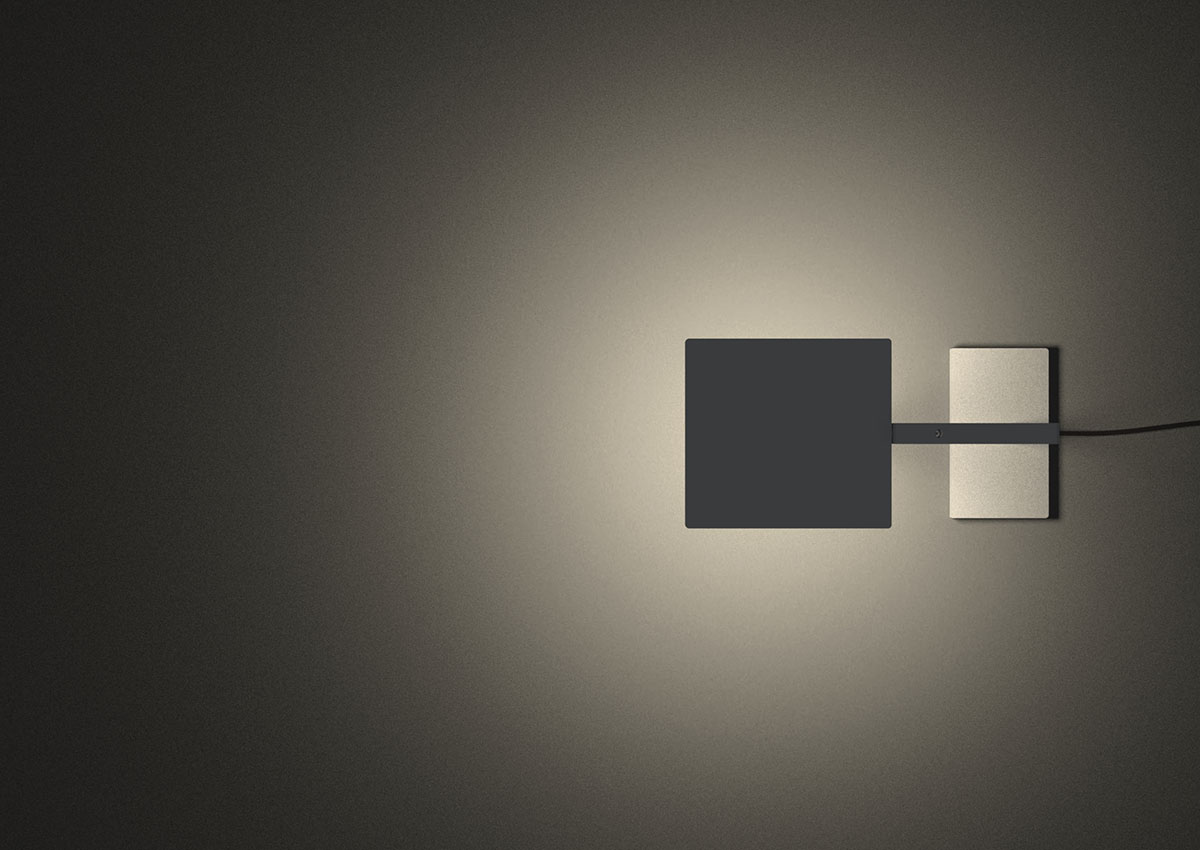

Planar Task Light by SDA

Smith Dixon and Associates Limited is a product and industrial design service, specializing in luminaire design for the lighting industry. Its principals, Rod Dixon and Lewis Smith have been working in the industrial and commercial lighting industry for a combination of 45 years. During this time, they have designed and developed lighting products, ranging from standard range interior downlights to bespoke luminaires for one-off projects. SDA products have been designed, developed and licensed around the world, and are installed in some of the most prestigious and exciting buildings. By engaging with SDA, users are able to capitalize on this wealth of experience and expertise as part of their design team.

The Challenge

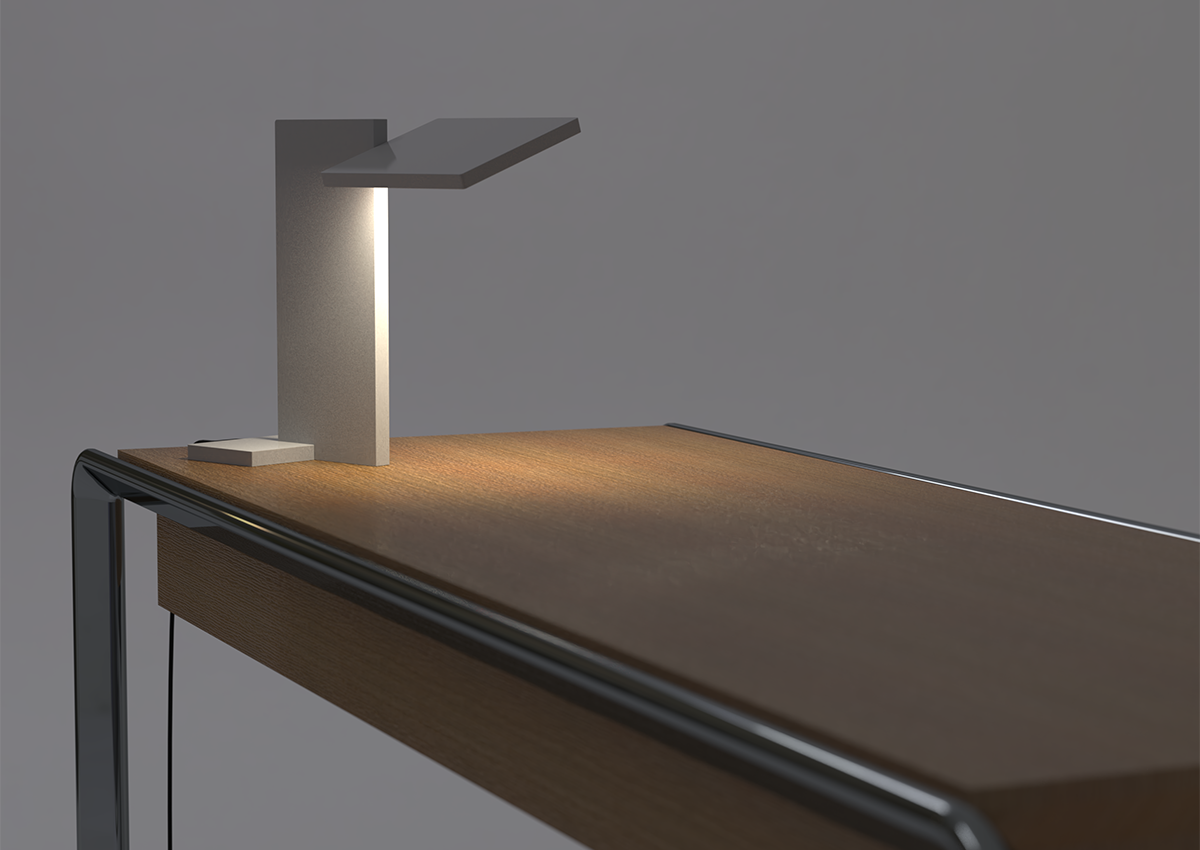

Recently, a project came to the scene whereby a Task Lamp had to be created. Slender in form, powerful and directional in output. Challenged with this interesting task, SDA selected Lightly Technologies and Luximprint as its project partners, respectively sourcing the LED module and the bespoke optics for the project.

As it is not easy to get flat optics with directional function as custom items, Luximprint 3D printing technology seemed to be the perfect match for the job. With zero manufacturing tooling involved, and enhanced freedom in design, SDA felt they were able to deliver an appropriate in-time solution without compromising to the design.

The Solution

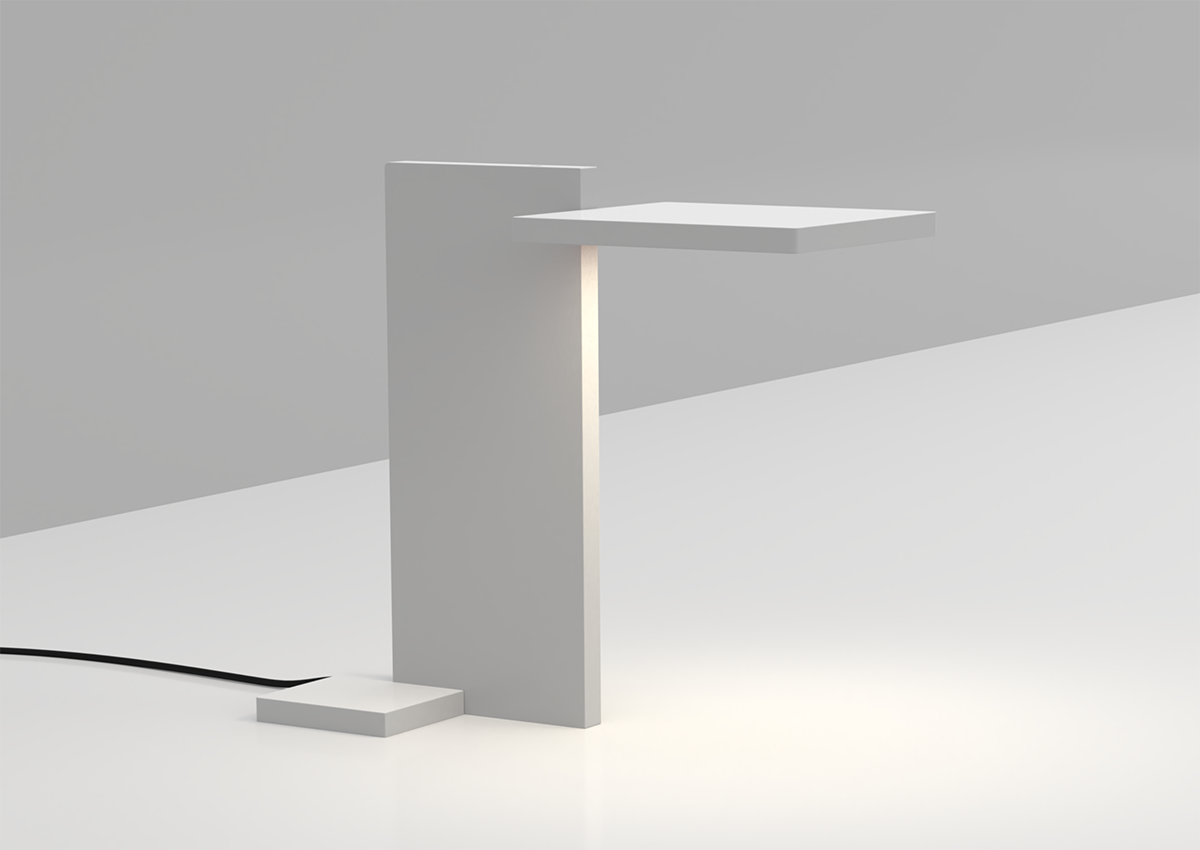

Minimal doesn’t need to be basic. Slender in form, the proportions of the developed task lamp took its inspiration from the compact nature of the Hikari SQ LED modules as provided by Lightly Technologies. Building upon the minimalistic design and flatness, this appearance is embodied in the overall fixture.

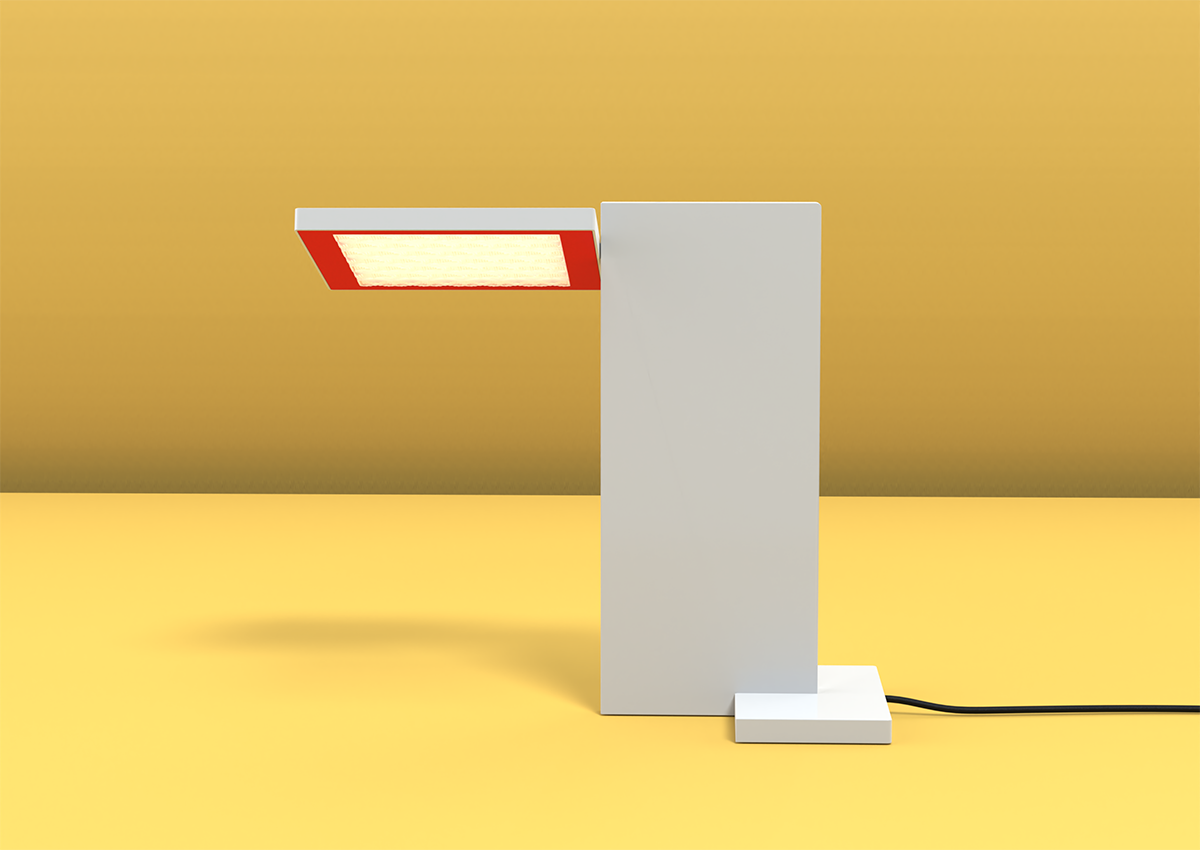

In addition, the slim appearance of the light source is further reflected in the bespoke optical system developed by SDA and realized using Luximprints innovative optical 3D printing capabilities. The unique design of the optic provides true control of the light; improving the visual comfort and performance of the task lamp.

The development of the hexagonal optical lens arrays in combination with the design of the luminaire and slim nature of the Hikari SQ LED light source compliment the idea of minimal form and simplicity.

The Benefits

Working with additive optics fabrication technology, includes an interesting range of benefits for engineers and designers of novel lighting systems. Most notable are:

▪Manufacturing Speed: Rapid Prototyping of custom illumination optics is now possible in days. Whereas conventional approaches require weeks or months to even get to the first soft prototypes, digital 3D printing significantly shorten lead times. Luximprint optics are generally provided in 5-10 business days;

▪Design Freedom: An advantage of working with Luximprints technology is the design freedom enabled through custom optics for luminaires. Whereas conventional tooling has its limitations, 3D printed optics enable a different approach in the design and manufacture of bespoke optical systems. Bottlenecks or a lack of capabilities from traditional optics fabrication systems can be avoided now using this next 21st century approach;

▪Customization: The freedom in design ultimately could be particularly beneficial to special projects or bespoke luminaires where product customization is predominately limited to the body construction, finish, and selection of light source. Tailored lighting solutions for any task are now within the reach of every designer;

▪Easy Variations/Iterations: The digital additive optics fabrication process enables testing of multiple lens variations in an extremely short timeframe and, if the results are not in lane which what’s expected during the initial optics design stages, quick design iterations. In a matter of days, custom optics evolve from preliminary design mock-ups to a perfect matching solution!

To experience more about the project, or to work with Smith-Dixon Associates directly, please visit our Optics Design Hub or contact SDA.