Project Description

Smooth Light Distribution Scheme for Oligo Birly trough a combined Light Guide and 3D Printed Concave Lens

Passion and fascination for lighting, as well as the commitment to work only with the best solutions available, is the daily motivation of the team of OLIGO Lichttechnik GmbH, based in Sankt-Augustin, Germany. Next to novel design inspiration and application of novel lighting technology, OLIGO aims for manual perfection as an answer to the massive consumer needs and trends. In the end, these attitude is reflected in the products and exhibits they introduce throughout the time.

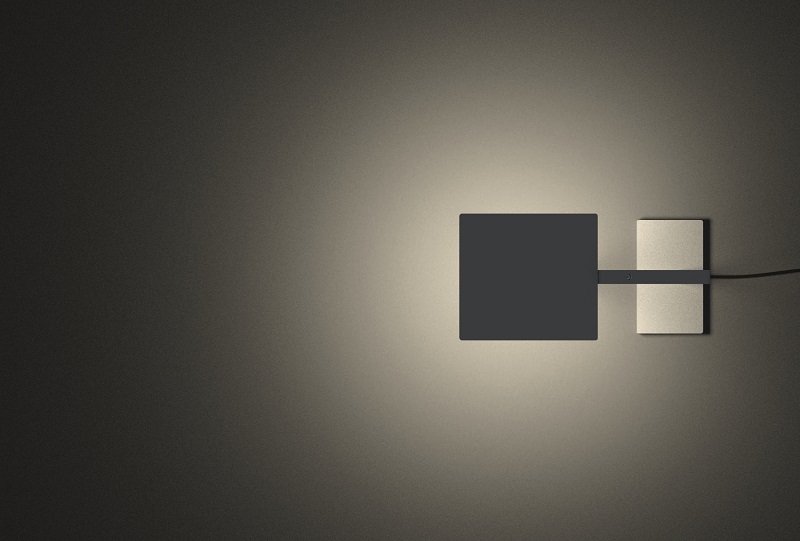

OLIGO Birly

The Oligo Birly, a stylish pendant light, is such a ‘lovely’ and well-designed fixture for residential lighting and retail lighting applications. We’ve been supporting OLIGO on making the end result even more appealing for their end-users, once some typical engineering ‘imperfections’ showed up right before the market launch.

The Problem

The Power LED chip of the system luminaire is positioned straight onto the cooling body for an optimal heat control, right at the top of the fixture’s colored lamp shade. This resulted in two engineering challenges:

1. Uneven illuminated Lamp Shade

A lot of light is concentrated at the top sections of the shade, since the light source is located close to the lamp glass in that area. Preferably, the lampshade should be more evenly lit and light-dark spots fade out into an equally colored lamp shade.

2. Contrasting Light Pattern

The light pattern at the beneath working area was defined by the circular opening of the lamp glass. This results in a strong narrow beam projection on the surface. A wider and more uniform beam spread is preferred to evenly illuminate the area with a smooth overlap of the individual lamp beams.

The Challenge

Our engineering team was challenged by OLIGO to create a secondary optic for the OLIGO Birly to optimize the light distribution and to enhance the overall visual product appearance.

The Solution

Our optics design team advised the use of a light guide with a frosted finish applied onto the surface to create a smooth vertical light distribution. Via the inner clear part, the light is transported from the LED chip to the end of the cylinder in the opening of the lamp shade. From there, a small 3D printed concave optic, foreseen with a selectively frosted surface finish, directs the light from there in a wider beam angle to the beneath surface. Apart from the functional prototyping for this innovative lighting fixture, various small start-up series were provided to meet the immediate customer demand and enable them to thoughtfully take the next step to fabrication tooling.

Unique Project Features

• Rapid Prototyping: in just a few days from scratch to optic: via the optics design, design simulations, design iterations towards a functional optics validation prototype;

• No Upfront Investments: Thanks to the zero need for tooling, no working capital was lost to molding and tooling parts;

• Unique Process Capabilities: Application of optically clear and selectively frosted finishes for a uniform diffuse light radiation;

• Ordering on Demand: No minimum order quantities required, ordering in quantities as needed;

• Exact Part Replication: after testing, validation and approval of the prototype, various small start-up series manufacturing were produced.

About OLIGO Lichttechnik

Over 25 years, OLIGO Lichttechnik GmbH produces unequalled solutions for residential lighting, as well as specific retail lighting and project lighting. With their highly valued single lamps and track systems, as well as tailored lighting concepts, the company offers for any challenge a matching solution.

The team of Oligo houses ‘creative lighting designers’ that well-understand manufacturing challenges. More than ever, this attitude is expressed in excellent hand crafted lighting and highly confident quality.