Rapid Prototyping Lumenova Street Light Lens Arrays for Light + Building 2018

Having lens arrays for street lighting fabricated is a time consuming and cost-intensive job. Before ordering the final manufacturing tooling, a soft tool should deliver the parts as needed to build the functional product demonstrators or, as in this project case, inspirational show demonstrators. With Light + Building 2018 in Frankfurt just around the corner, the last minute design changes that Lumenova brought to the table for the novel Outdoor LED Lamp concept incorporated quite some challenges. The need for a fast and flexible prototyping process to fabricate the Lumenova Street Light Lens Arrays was imminent.

Additive Optics Fabrication Technology For Lumenova Street Light Lens Arrays

Convinced that additive optics fabrication was the one and only way to get the job done, VIP-Virant reached out to Luximprint to get the Lumenova Street Light Lens Arrays readily available for the show.

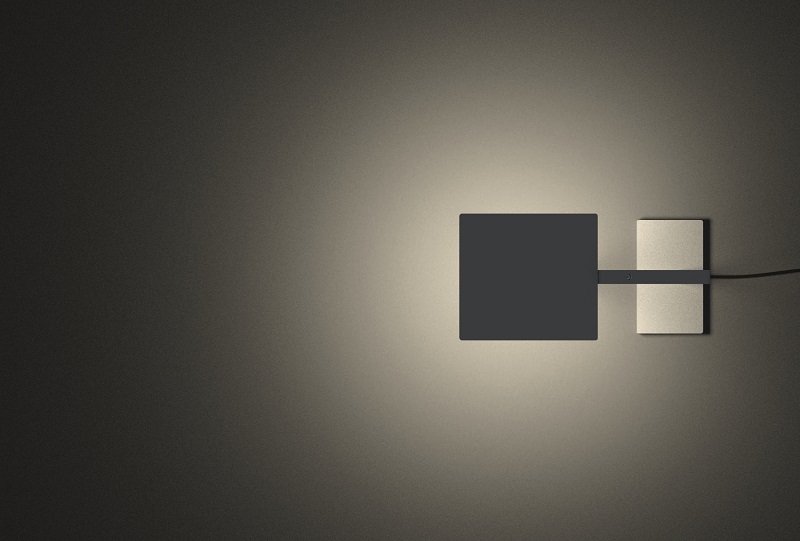

The Lumenova SSL Outdoor LED Lamp is a fresh and elegant design luminaire, whose shape mimics the properties of waves of light and thus pursues the laws of nature.

The Challenge: Lenses just in time!

Lumenova proves with high power light diodes assembled modules impressively the expertise in development and production of high-quality and complex street lighting systems. Efficiency, intelligence, flexibility, quality, lifetime and a space-saving composition are the characteristics, that generally feature Lumenova’s products. A broad range of different led optics to choose from, the inventive temperature management and modular composition, combined in a sealed cassette result in a diversified application area and a simple functional yet modern design.

The Lumenova CCL LED Outdoor Fixtures for street lighting applications were launched at Light +Building 2018

With less than two weeks left until the Light+Building show start, having a next-generation lens arrays prototyped in time is a nearly impossible job. Conventional optics fabrication technologies lack when it comes to meeting the timeline, while fast conventional 3D printing technologies lack the optical clarity and performance. In addition, the sizes and resolutions as required for the Lumenova CCL and Lumenova CCR Outdoor LED luminaires were of significant dimensions.

The Solution: Printed Optics!

After VIP-Virant reached out to Luximprint for the rush job, a project team was created including the engineering team of VIP-Virant, the buyers and some Luximprint print engineering specialists in order to make sure a fast and effective Expedite Prototyping job could be done.

Aluminum, the material that embodies the Lumenova CCR fixture exterior, ensures its longevity and durability. The igneous design adds to the modern look of the landscape.

A couple of fast design iterations were implemented to make sure the lens arrays could be processed in a fast and cost-efficient way, and the quality would be appropriate for the show demonstrators, both from an inspirational and functional perspective. The fixture housing enables the achievement of conditions of the “Dark Sky” or “Full Cut-off”.

The excellent interaction between both teams finally enabled the rapid prototyping of a batch 3D printed lens arrays that met the full spectrum of the Lumenova portfolio. The hard-working team bringing an unprecedented way of the speedy iterative design processing, fast shipping and on stage delivery and mounting ensured the show presentation got ready just in time. When Light + Building 2018 in Frankfurt opened here doors, the full-set up was complete, functional and ‘ready-for-launch’.

Frosted Finish Application

An interesting detail was the application of a defined frosted finish to reduce the glare. Frosted finishes (‘wanted roughness’) are applied along with smooth surface finishes in one single job, straight from the process.

Lumenova Street Light Lens Arrays on Light + Building 2018 produced by Additive Optics Fabrication technology.

The Benefits – Project USPs

- Manufacturing Speed: The lens arrays were fabricated in less than two weeks. Whereas the standard Luximprint Prototyping Services were not fast enough, it was decided to offer Lumenova the ‘Expedite Prototyping Services’ to get the project done;

- Process Flexibility: The Lumenova Street light lens array was finally fabricated in three different lens types. All having the same base, the amount of light sources, however, was scaled. The capability of printing various extensions (‘Product Variations’) of a product at the same time are one of the most interesting features of the Luximprint process;

- No tooling/No MOQ: Having the optics prototypes fabricated straight from the CAD with zero need for tooling, is positively impacting the lead time and cost related to the job.

About Lumenova

Lumenova – member of the VIP-Virant Group – is a modern company with experienced employees that specializes in innovative LED technology. Their Light Engine is are a complete LED system, which is conceived on a modular concept and offers customers in indoor and outdoor lighting, as well as all manufacturers of luminaires a huge range of options that are perfectly adapted to their needs and requirements. The goal is to continue with progress in LED technology, to develop and complete new ideas and fabricate integrated solutions, both for their own portfolio or their partners.

More information on the company and its offering is available on the Lumenova website.