High-Resolution 3D Printed Rotation Optics

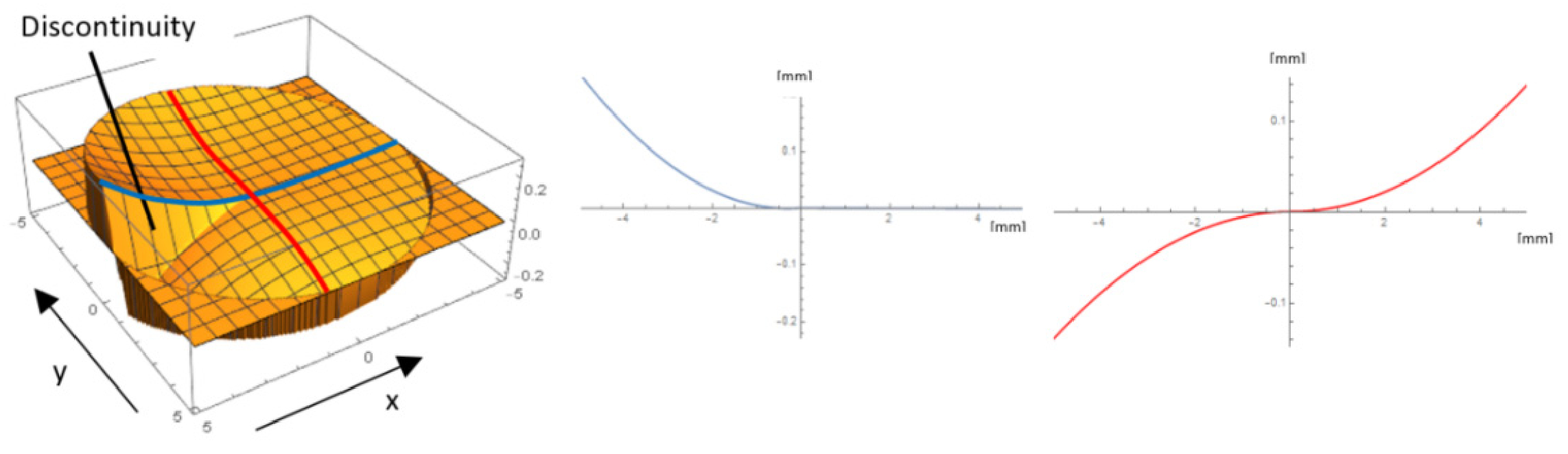

In this paper, written by leading researchers of KNMF/KIT, design and manufacture of a 3D printed varifocal freeform optics is presented. The optical refraction power can be tuned continuously by mutual rotation of two helically shaped lens bodies of azimuthally varying curvatures. Since no additional space for axial or lateral lens movement is required, rotation optics allow for a highly compact design of varifocal optics. The additive manufacturing of the optics was conducted by means of the high-resolution optical 3D printing process at Luximprint. Results of tactile surface measurements are presented as well as imaging through the lens.

3D Printed Alvarez Lenses

3D Printed Varifocal Rotation Optics

The paper presents the design and additive manufacturing of varifocal rotation optics as well as tactile surface measurements of the 3D printed lens parts and imaging results of the manufactured optical system. The organization of the paper is as follows: in Section 2, the basic principles are developed and a mathematical description of the surfaces is derived. Section 3 shows the results of surface measurements of printed components, while the 4th and last section addresses the imaging results of the rotation optics. Conclusions are drawn in the final section.

You can read the full Optics Express article online at the OE website, or just view and download the PDF summary directly.

Acknowledgements

This research paper was written by Ingo Sieber, richard Thelen and Ulrich Gengenbach and published by The Optical Society under the terms of the Creative Commons Attribution 4.0 License.

This work was carried out with the support of the Karlsruhe Nano Micro Facility (KNMF, www.knmf.kit.edu), a Helmholtz Research Infrastructure at Karlsruhe Institute of Technology (KIT, www.kit.edu). The authors would also like to acknowledge Marco De Visser and his team at Luximprint for data preprocessing and 3D printing of the optical structures.

Source: Optics Express | Vol. 28, Issue 9, pp. 13423-13431 (2020) | https://doi.org/10.1364/OE.391697

![3D printen een van de 5 trends in de kunststoffenindustrie [NL]](https://www.luximprint.com/wp-content/uploads/2021/09/Luximprint_3D-Print-Magazine_Article-Kunststoffenbeurs-2021.jpg)