Additive Optics for the Automotive Lighting Industry

In these times of increasing mobility, we find ourselves spending (too) many hours in traffic. To make the time spend as pleasant as possible, designers and OEMs are developing automotive lighting solutions that will turn driving into an experience. No matter this concerns your personal car, business van or the public transportation you are using, light affects it all and has great potential to influence human behavior and well-being in a very positive way. Just like home, and at the office!

Custom Optics: The Key to More Pleasant and Safer Automotive Lighting

To make that happen, a variety of optical components is used to get the light distributed to the target illumination surfaces, either for functional use or just to make the overall perception more ‘pleasant’ (glare-free, non-blinding, smooth and evenly lit) and safe. Secondary optics and tertiary optics greatly enable the control of the light under most challenging conditions.

[caption id="attachment_4699" align="alignnone" width="750"] Fresnel Lenses are a typical lens type that’s frequently used in various automotive lighting applications – both large and small.[/caption]

Fresnel Lenses are a typical lens type that’s frequently used in various automotive lighting applications – both large and small.[/caption]

At Luximprint, we are – among other lighting markets – specialized in the rapid prototyping of custom optical components for automotive lighting systems. The applications of printed optics range from specialty vehicles to trucks, and from passenger cars to show cars and hyper/sports cars. Basically, we are represented across the entire design and engineering world in the automotive lighting spectrum.

Interior Lighting: Experiential, Sophisticated and Modern are Trending

The trend of replacing conventional lighting technology to LEDs as light sources in vehicle interiors continues unabated. Automotive LED interior lighting sets modern light accents according to the users’ needs. As automotive interiors become more sophisticated, customization and differentiation are a key topic in the industry today. Additive manufacturing approaches, on their turn, are increasingly meeting the demanding design and material specifications of the users and have proven to be a solid answer to mass-customization requests.

[caption id="attachment_4700" align="alignnone" width="750"] Customization in automotive can go as far as the individual user wants to go for. The boundaries in imagination are unlimited![/caption]

Customization in automotive can go as far as the individual user wants to go for. The boundaries in imagination are unlimited![/caption]

Versatile 3D Printing Capabilities

The Luximprint additive optics fabrication process is providing some interesting printing capabilities for designers and engineers of automotive interior lighting systems. Most notable are the versatility (flexibility) of the process, as well as the great complexity (at no additional cost) that can be reached using advanced optical 3D printing technology.

Typical interior lens applications that fit our process capabilities:

▪ Breaking Lights (3rd)

▪ Glovebox Lights

▪ Trunk Lights

▪ Occupational Lighting

▪ Door Lights (both doorstep and door)

▪ Heads Up Displays (HUD’s)

In addition to functional lenses, the smooth surfaces as generated by the 3D printing process are utilized for decorative purposes (in combination with e.g. coatings), sensors or other types of functional or decoration purposes where the use of plastics is allowed.

Optographix For Customized Interiors

In addition to functional optical components, Luximprint Optographix solutions get discovered by leading OEMs, TIER suppliers and designers as a distinctive tool for customizing automotive interiors. Brand names, icons, Millenials, special (colored) light effects, basically any given design expression can now be seamlessly integrated into the car interior.

[caption id="attachment_4698" align="alignnone" width="750"] Millennials are just one interesting example of customization to mention.[/caption]

Millennials are just one interesting example of customization to mention.[/caption]

Exterior Lighting: Light Signature – The Outside Expression Counts!

Products that served entirely practical purposes until a couple of years ago, have now become the center of attention: headlights and rear lights. Designers have discovered the primary car lights as an important design element. It has long outgrown its purely functional role. Today, many different car models and even entire brands identify themselves and express emotions and attributes, like speed and power, through their headlights.

From our position, it’s great to serve as a fabrication partner who is capable of offering solutions that allow a great deal of flexibility and design freedom, in addition to unique 3D printing technology features.

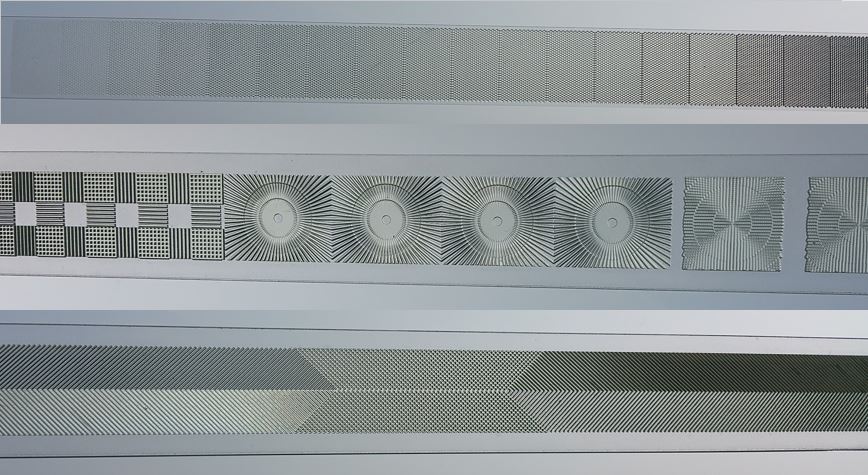

[caption id="attachment_4701" align="alignnone" width="868"] Luximprint Additive Optics Fabrication technology allow a great deal of flexibility and design freedom. Complexity for free![/caption]

Luximprint Additive Optics Fabrication technology allow a great deal of flexibility and design freedom. Complexity for free![/caption]

Printed Optics for Automotive Lighting

The light pattern of a given LED source, typically distributed at an angle of 180°, needs to be captured, focused, reoriented and distributed towards other traffic partners. At the front-end of the engineering process, during the early design and development stages, Luximprint technology offers a great way to get custom optics available in a fast, flexible and cost-effective way.

Typical Optics for Automotive Lighting

As optical elements we may 3D print simple or advanced reflective surfaces, Fresnel optics, prismatic lenses, micro and macro lens arrays, different kinds of light guides such as light guiding plates, light bars or curtains.

Frosted Finishes

For the final distribution and correction of the beam pattern, we can apply frosted finishes to simulate a frozen appearance. We offer a variety of defined frosted finishes that can be applied directly onto optical surfaces or its connected areas for protective (anti-glare), aesthetical or functional performance patterns (diffraction) in one and the same fabrication process.

Reflective Coatings

Also, technical and/or decorative coatings can be applied for functional optics (reflectors) and decorative purposes. Utilizing the surface complexity and/or smoothness, planar, highly textured surfaces or micro reflectors can easily be created.

Note:

Our materials are primarily suited for use in interior automotive applications, most notably design and engineering environments and showcars.For exterior lighting, we mainly fulfill a role of rapidly providing functional optics for temporary testing and validation purposes.

Our actual materials are of the highest grade optical quality, but not meeting the (demanding) specs for outdoor use in challenging automotive environments.

As such, novel optical systems can be tested before the final manufacturing tooling is ordered and, if needed, adjusted to the latest insights.